Barnwood Construction is an employee-owned company and specialise in three areas – construction, shopfitting and interiors, and general works across a wide range of sectors.

Why they got in touch with Central Flooring

Barnwood trust us with their projects because we deliver what we promise, when we promise. That’s why they got in touch for this one on behalf of their client – a leading and innovative name in aerospace, defence and security.

About the project

Barnwood and their aviation client were very happy with the Central team – and there’s more projects booked in. We completed the project to their programme so that there wasn’t any disruption, and they could operate as usual within their specified time frame.

Project

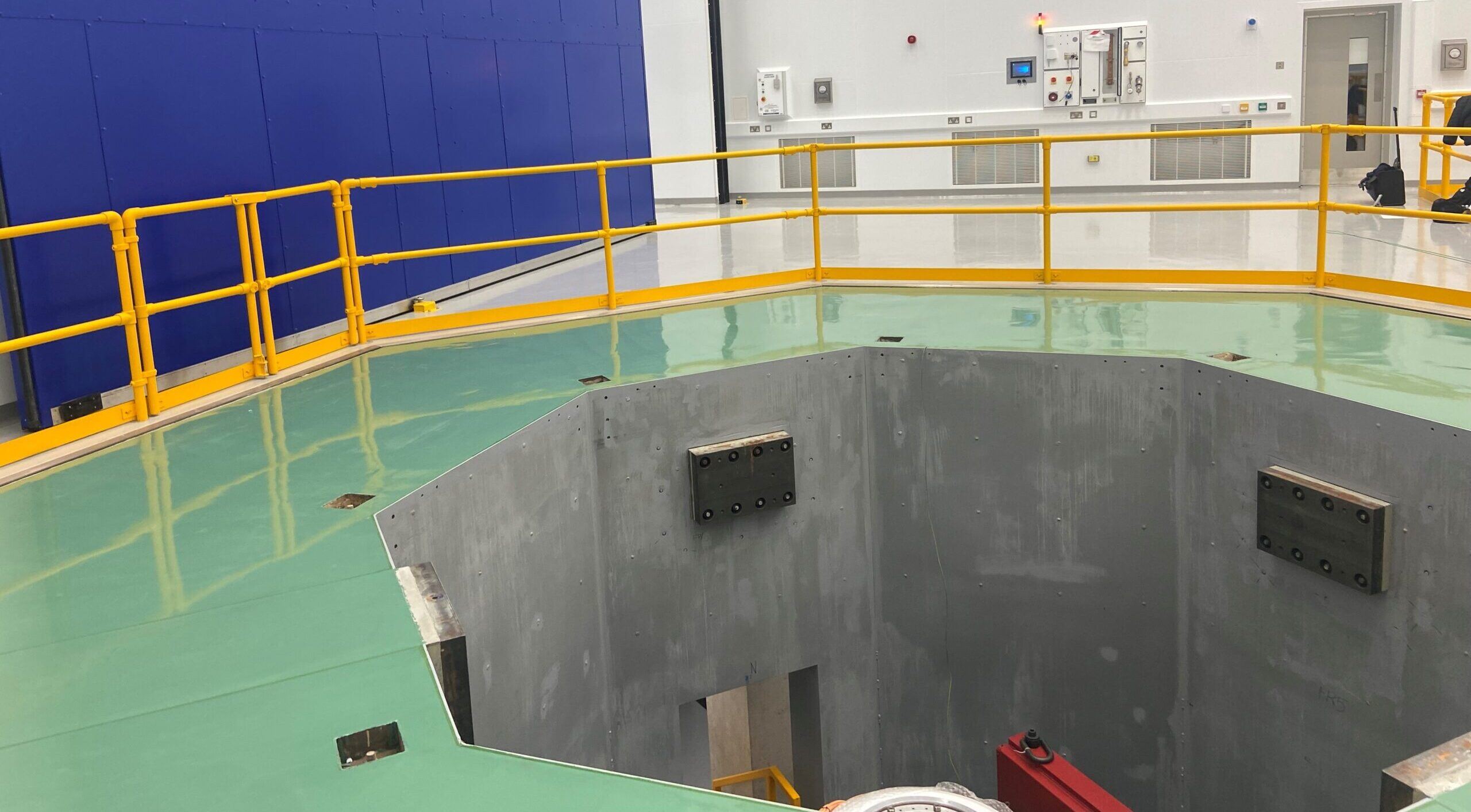

Renovating an existing unit.

Product

We chose Pumaflow and Pumatect for this project because it’s highly durable and has resistance to impact, abrasion and chemicals. Plus, it’s seamless which makes it easy to clean and keep clean – ideal for this high-tech aviation production facility. In all, we used 480m² of Pumaflow SL Full System, 150m² of Pumatect because of its resistance to slips and 190 linear meters of expansion joints.

Preparation

To prepare the existing sub floor to accept the new resin flooring products we carried out a mechanical grind. To finish, we vacuumed all residue and then responsibly disposed of any waste.

Project Duration

We completed the renovation in 3 phases, each phase took 5 days.

Project gallery

You May Also Like

These Related Stories

Kier Construction

Gipping Construction